David Blumenstein visits KJ West One in London for the UK launch of the circa £12, 000 Magico A3 loudspeakers and speaks to the company’s CEO Alon Wolf.

Shout MAGICO in the middle of a crowded HiFi Show or simply among a gathering of audiophiles, and you will see their eyes bulge and their wallets hemorrhage. Now try this on for size, a pair of Aluminum encased, inside and out, rigidly damped pair of MAGICO A3 speakers for the princely sum of £11998. Unheard of at that price…well I heard them at their world premiere in London: KJ West One, Seva and his crew, along with Riccardo and Pedro of Absolute Sounds made this possible.

Not being able to get over the price point and the sound quality emanating from these puppies, and with Alon Wolf, MAGICO’s CEO presenting, there was no way he was leaving without a quick Hifi Pig interview. Bottom line: What would have been possible at a price range of £30-£40K is now being made more affordable with MAGICO’s use of a full CNC rig to machine 6068 T6 Aluminum and plates of .5” thickness. Such an offering is possible with the ability to scale, and as the first batch of orders has sold out in 2 days, MAGICO and Alon are well on their way to their year end sales target of 1000 units.

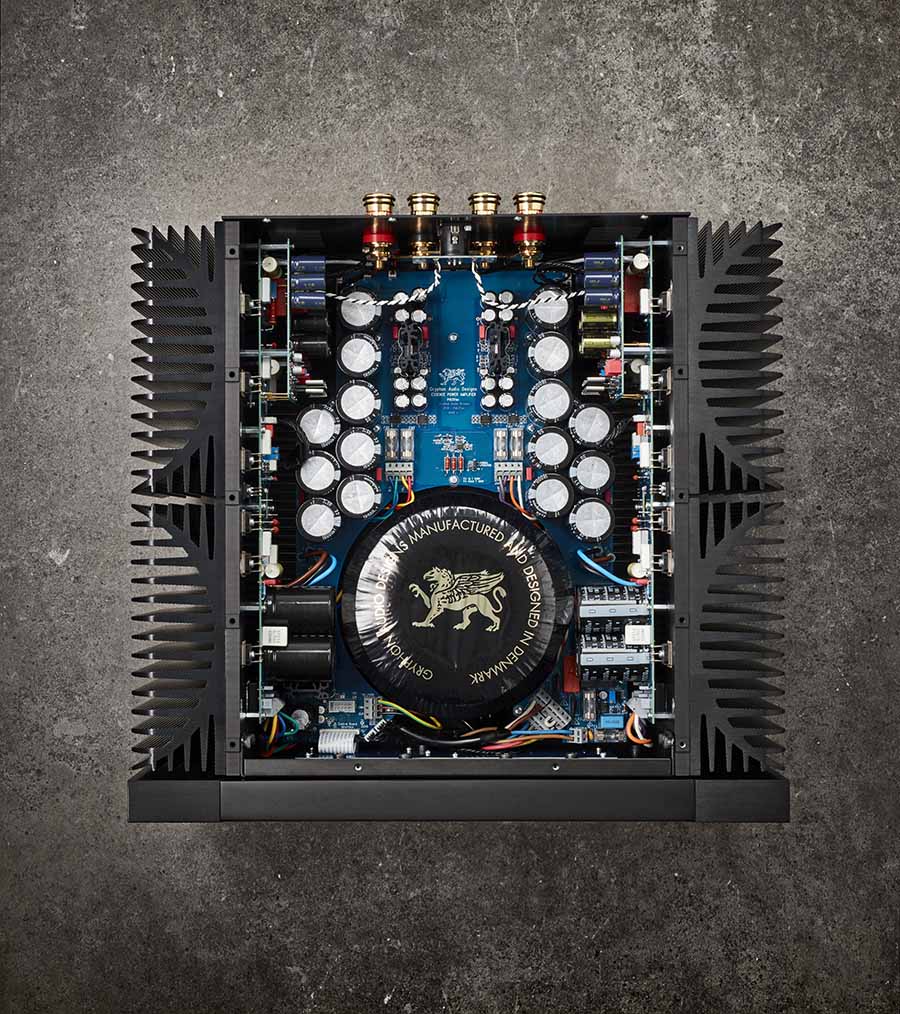

The speakers were paired with some killer electronics: Dan D’Agostino pre/power amps and a seemingly full rack of DCS gear. All this accompaniment even made Alon blush. At the price, he intimated that the A3s could be ably run by a decent quality Integrated amplifier. I’m curious enough to want to match them with my trusty Parasound Halo 2.1 Integrated amplifier.

Are the A3’s going to win any museum design awards, or grace the cover of Architectural/Interior Design? Probably not to both of the above, but that just doesn’t matter. It’s about how they sound, how rigid they are, and the incredibly low noise floor, so all you hear and SHOULD hear is the music. The internal structure and bracing as described to me is another story…

The A3 sports a three-way driver design capable of going as low as 22Hz and extending itself to just about 50 kHz. Magico’s M-Project tweeters serve as basis for both design and geometry, with the A3’s 28 mm dome sporting a pure beryllium diaphragm. The midrange driver employs a carbon fiber cone coated with XG Nanographene, and sizable magnets providing greater field stability. Its low end handled by two 7-inch woofers making use of MAGICO’s Nano-Tec cones. All in all the A3’s owe a great to their siblings: the. S3, M3 and Q3.

But why now? What does this mean for MAGICO? What if any compromises had to be made to bring the A3s to reality?

DB: You’re coming out with a speaker, that’s priced at that magic sub ten thousand dollar level (MSRP £11998). What is the impetus and motivation for doing this at this time, right now?

AW: The reason that is happening now is mainly our capabilities to actually to do the type of production and quantity that would allow for that price reduction. It has taken us 15 years to get ourselves into a position where we actually have enough mass behind us to start looking into production of that size and quantity. Because the bottleneck in production is the enclosure, this is the first time anyone has built an all aluminium CNC machine to half inch plate loudspeakers which we have done for many years, but at much higher cost than sen here. So, the motivation was always there, we were never able to do that, but we never had enough capacity and capabilities to do something like that…now we do.

DB: Which existing speaker in the MAGICO family is the A3 most based upon? From which does it borrow?

AW: That’s a tough question because, if you’re looking at real estate, i.e 3-way: tweeter, midrange, two sevens, that is based on the V3, the prior V3 that has been out of production for 6-7 years now. So, that’s the profile in terms of real estate, however, it does employ quite new technologies, maybe not quite to the level that we employ them at the S-series, or the M series, but it does represent more or less our latest thinking but of course built to a price point.

DB: Research online pointed to elements of the M3 finding their way into the A3. Could you elaborate?

AW: Well, yes you can say that. For instance, this is a Beryllium tweeter based on a 28mm dome we created for the M project that we worked on for 2 years, so it is based on the same concept, actually the same dome exactly, it’s not covered with diamond deposits like it is on the M series, but that’s something that is derivative of the M Pro project, the M3, the M6 and so on. Graphene is used here as well, not to the extent that it is used on the M and the S series, but it is used, so yes all the technologies have trickled down to the A3 speaker we see here tonight.

DB: Who is your prime customer? The target demographic for this particular speaker?

AW: I hope that it would speak to people who until now could not quite afford buying our more expensive products. So I’m pretty much in favor of bringing the MAGICO magic to as many people as possible and I understand the issue of price constraint.

DB: Why the metal cabinets in lieu of the organic, the traditional wood cabinets? Is this the special sauce, which sets MAGICO apart from its competition?

AW: Because a loudspeaker is not a musical instrument, and it should be built with the objective of having the speaker being as rigid as possible. It is something we have been advocating for many many years. A loudspeaker is the place in the system where an electrical energy is being transferred to mechanical energy and the issue of loss is at the most delicate juncture. The only thing that should move in a loudspeaker are the driver cones. Nothing else should move, which means the frames of these cones have to be attached to an apparatus that is completely still, i.e. extremely stiff, yet damped, so it doesn’t vibrate, and it doesn’t capture some of the energy that the driver is trying to generate and that is not possible to do with typical used materials like MDF or wood. They are extremely damped, so they’re just not stiff enough. They store energy, so, a lot of the energy that is being generated by the driver is being stored in the box and then released later which creates smearing and reduces the overall transparency of the loudspeaker. Any type of resin does the same thing, it is a bit stiffer than wood or MDF but also quite damped, so aluminum is more or less the ideal material to build a speaker from, though titanium would be better, but the cost would come as a bit of a shock to most people. It (Aluminium) is an extremely stiff material that is very easily damped because it is so stiff per its weight, and the amount in this model is so high.

So, you get an opportunity to create a stiff enclosure that you can damp, and you do have to damp it in some form. You just can’t leave it without any damping, because it will ring. The only problem with building loudspeakers in this way is the cost because it is quite a bit more expensive to build an enclosure like that, and not only is it more expensive, it also requires specialized skills. So, you can build a loudspeaker from MDF in your garage but it is going to be a little more difficult with aluminum.

DB: It is interesting that you mention that a loudspeaker is NOT a musical instrument. I don’t know anymore, how many times I’ve hard speakers described as extensions of the music, as musical instruments. They refer to them because as being alive because of their core materials, but until MAGICO no manufacturer has been able to scale the production of non-traditional/aluminum speakers and have them sound natural.

AW: I actually think, that if I look back we have been in business for 15 years and if you look there’s a list that The Absolute Sound published a couple of years ago of the 12 most influential loudspeakers ever and one of our speakers was in there among those 12, and of course I was very proud of that. What was really unique was it was the only loudspeaker in that list that was created in the 21st century. All the other speakers were created in the 20th century. For us, it was just around the corner, but no it is all ready 18 years since then. And if you think about your phone and camera or computer, where all these devices were back then, 18 years ago and the improvement and capabilities of what we can do today versus what we were able to do back then, yet it is mind boggling in our industry that very little of that has been done. I actually think that the reason we were able to do what we have been achieving and get to the place where we are In the market is because people actually realize and appreciate the science we bring into this kind of endeavor. Because this is an engineering feat and not some sort of artistic impression as to what I feel music should sound like.

DB: A lot of components, come and go in the industry. After a while they all start sounding similar because a lot the raw components are the same and there’s a limit to just how much tweaking. I look at the A3’s an unlike their siblings they are not flashy, not a supercar to ogle. Yet…

AW: I would actually urge you to take a closer look. This a magical loudspeaker in terms of perceived look. We were able to create a loudspeaker which was very close in construction to our Q series. Yes, it is not quite as pushed in terms of finish: the Q was bead blasted, with hard anodizing, etc. In fact, the finish on the Q was probably more expensive than these speakers actually cost to manufacture in total. It is along the same line with what we are doing, it’s the same metal, it’s anodized, it’s brushed so its not bead blasted of course.

DB: That’s a lot of value one gets in the A3 from a style perspective. I will take a closer look AND feel. So, with all the aluminium and its rigidity and stiffness, what do these weigh?

AW: They are quite heavy, they are about 110 lbs. But that doesn’t mean much because MDF is heavy too. You can build quite a heavy product out of MDF alone. Resin is heavy too. You can move these yourself but yes, they are heavy. Our M3 weighs 300 lbs, so that’s staying put.

DB: Looking down the road, long term…18 months how would you characterize success for the A3 speakers?

AW: There is no question that we need to sell a lot of those speakers to make this exercise worthwhile. The margin in an exercise like this are so tight, and so because of the actual costs involved only selling serious quantities will be worth the endeavor. When we finally got to manufacture the first batch, and we’re talking about a tremendous amount of quantity to get the price to where we needed it, I had no idea how the market would react, so we took a big chance on that, a substantial investment on our part. And in two days, since we announced it, the first two days we sold the entire batch. I was quite worried if that was going to be the case, because of the investment involved.

You must be logged in to leave a reply.