Soulines Turntable Model tt42 Released

Soulines turntable model tt42 is the Serbian brand’s new flagship reference turntable.

Soulines turntable model tt42 is the Serbian brand’s new flagship reference turntable.

Soulines’ aim was to produce a high-end turntable that would look and sound good, be user friendly and allow the simultaneous mounting of two tonearms of any length and any mounting type, so they created the Soulines Turntable Model tt42. We reviewed their Kubrick turntable way back in 2014.

Douglas Adams

All Soulines turntable models are named in honour of one of the creative personalities from the world of art who personally mean a lot to the brand. This time they named the turntable after a number which usually has no meaning other than mathematical until it is placed in the context of the science fiction novel “Hitchhiker’s Guide to the Galaxy” by the famous Douglas Adams, where the number 42 is the answer to the “question about the meaning of life, the universe and everything”.

Igor of Soulines told us “As no one can tell which is the best turntable in the world, because we still don’t know what that turntable should be like, what characteristics it should have, etc. namely we don’t know how to correctly formulate the question what’s the best turntable in the world, it is also impossible to correctly formulate the question about the meaning of life, the universe and everything, and get some meaningful answer. So, the number 42 is the perfect answer to that question, as long as the question is formulated in that way. Until we determine what’s the best turntable in the world should be, the tt42 could be the answer”.

Fibonacci Sequence

Design of the tt42 was done using 3D-modeling software and employing Golden Ratio and Fibonacci sequence, in order to attain a fully mechanically balanced system. Thus, the centre of mass of the turntable is placed onto the vertical axis of rotation of the main bearing shaft/platter, reducing the moment of inertia to the very centre of the mass. To gain uniform vibration damping across the whole frequency spectrum, different materials like acrylic, aluminium and stainless steel, had been chosen for the plinth and sub-plinth components according to their specific mechanical characteristics. All the components are precisely CNC machined and hand-finished.

Plinth And Sub-Plinth

The acrylic made main plinth, solid aluminium sub-plinth and motor assembly are 3-point or 4-point coupled over differently sized rubber-cork washers for damping, thus gaining maximum control of the vibrations transfer through the complex plinth/sub-plinth/motor-pod assembly.

Both arm-pods and main bearing assembly are tightly mounted directly onto the CNC machined aluminium sub-plinth, which is in turn 3-point coupled to the main Acrylic plinth over the differently sized rubber-cork washers used for damping.

Main Bearing

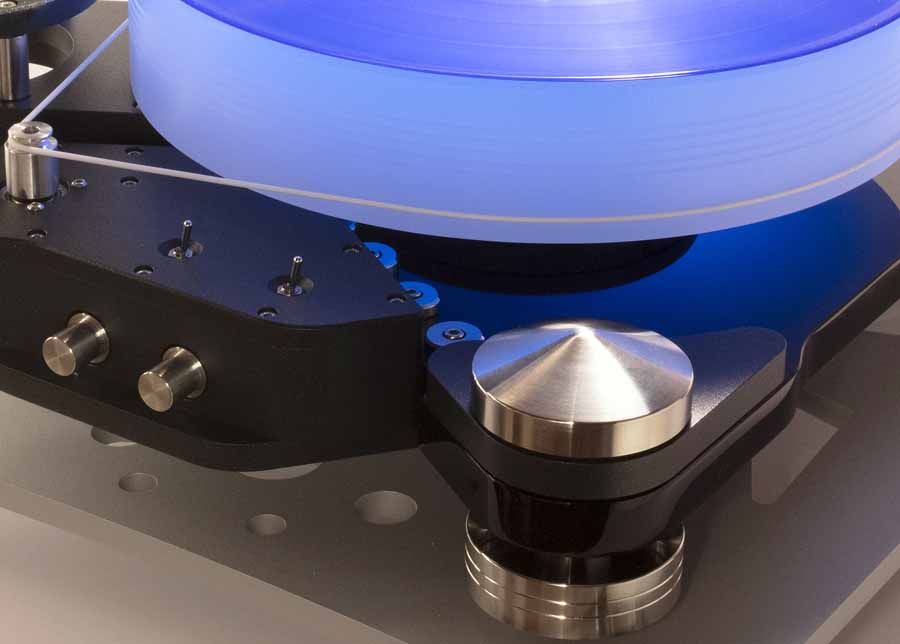

The main bearing assembly is of inverted type, precisely CNC machined and finished to the tightest of tolerances. The bearing top hub is machined from solid stainless steel and comprises a brass sleeve insert and Derlin thrust pad. A polished stainless steel shaft holds a captive hardened steel ball bearing, at the top, ensuring that the ball is housed absolutely central to the shaft.

The platter, 60mm thick and weighing 5.4kg, is machined from laminated cast Acrylic to a very high accuracy. The use of a mat is completely up to the user preferences. The complete main bearing assembly and platter are individually manufactured to fit each other specifically, rather than manufacturing in batches.

Brushless DC Motor

The drive mechanism utilizes a powerful, high torque brush less DC motor and with an integrated speed control electronic driver, while the motor controller is a true analogue device, providing constant speed and uniform rotation. A fine speed adjustment feature is provided for both speeds 33.33rpm and 45rpm.

CNC Stainless Steel Feet

The turntable is supported by three adjustable massive cone feet CNC machined from solid stainless steel to allow levelling and provide optimum coupling to the surface that it sits on. The cone feet are coupled to the particular aluminium pods over the rubber-cork washers of different diameters, while in turn the aluminium pods are 3-point coupled to the main Acrylic plinth again over differently sized rubber-cork washers for damping. Thus, structural vibration break through (from the environment through shelf/rack/stand) is minimized and can be neglected.

Arm Pods

Two identical arm-pods consist of several parts: the upper part, the lower part and the arm-board (SME x 2, Jelco/Linn/Ortofon, Rega/Origin Live/Audio Note/etc. mounting standard), all CNC machined from aluminium and 3 sets (of 4) of spacers of different heights (15, 20, 25 mm) made of stainless steel. The upper and lower part are tightly connected with six M4 bolts and can slide over each other, so the required change of geometry for different tone-arms lengths, 9 or 12 inches, is quite easy, unscrewing the M4 bolts, sliding the upper part to the appropriate position and tightening the bolts again.

The right arm-pod with the SME arm-board is factory fitted while mounting of the second (left) arm-pod (comes partially assembled) is quite easy using six M4 bolts (supplied). Custom arm-boards are available by request and upon submitting necessary technical drawings of the particular tone arm specific mount.

Included In The Package

– three different (user) exchangeable aluminium made arm-boards:

– two SME arm-boards – tone-arm pivot to spindle distance from 199-241mm (9”) and 275-317mm (12”)

– Rega/Origin Live arm-board – tone-arm pivot to spindle distance 222mm

– Jelco arm-board – tone-arm pivot to spindle distance 214mm (9”) and 290mm (12”)

– partially assembled second arm-pod

– 3 sets (of 4) of stainless steel spacers of different heights 15, 20 and 25mm

– high-performance rubber-cork mat

– cartridge protractor alignment tool including Baerwald, Loefgren and Stevenson protractors

Specifications

Drive type: belt drive, using 2mm diameter round silicone-rubber belt

Motor: an electronically controlled quality high torque brushless DC motor

Speeds: 33.33 and 45.00 RPM with fine speed adjustment feature for both speeds separately

Bearing: advanced solid inverted bearing CNC machined from solid stainless steel with brass sleeve insert and Derlin thrust pad; polished stainless steel shaft holds captive hardened steel ball bearing

Platter: 60mm thick 5.4kg weighing, machined from laminated cast Acrylic

Construction: multi layered Acrylic/aluminium/Stainless Steel construction where are all the main parts like plinth, sub-plinth, motor pod and each of 3 isolation feet are 3-point or 4-point coupled over the differently sized rubber-cork washers for damping

Finish: combination of Anthracite black powder coated aluminium, shiny Stainless Steel and Black Acrylic

Extras: second arm-pod; 3 user exchangeable arm-boards for SME(x2), Jelco and Rega/Origin Live/Audio Note tone-arms; 3 sets (of 4) of stainless steel spacers of different heights; rubber-cork mat; cartridge protractor alignment tool

Power: High quality switching PSU: input AC90-240V/50-60Hz – output DC24V/2A

Dimensions: 470x355x165mm (WxDxH) overall only right arm-pod mounted for 9” tone arm; 470x415x165mm (WxDxH) overall (both arm-pod mounted for 9” tone arms); 530x355x165mm (WxDxH) overall only right arm-pod mounted for 12” tone arm); 530x480x165mm (WxDxH) overall (both arm-pod mounted for 12” tone arms); 465x355mm (WxD) footprint

Net weight: 20kg

Price:

TBC but in the region of 15,000€ without tonearms/cartridges/cables